Safety features should remain a top priority despite the attractive pricing. Look for machines with emergency shut-off mechanisms, proper ventilation systems, and certified pressure vessels. The best deals include thorough safety packages with proper PPE attachments, lighting systems, and transparent viewing windows with replaceable protective lenses. These safety components shouldn't be compromised, even when pursuing cost-effective option

When selecting a sand blasting machine manufacturer, you'll need to verify their ISO 9001:2015 certification and quality control protocols. Look for manufacturers offering extensive equipment options including pressure blast systems, suction cabinets, and automated rooms with integrated dust collection. Confirm they provide technical support, spare parts availability, and proper safety features. Their industry experience and engineering capabilities across aerospace, automotive, and marine sectors will determine your equipment's long-term succes

You've now got the inside scoop on sandblasting machine manufacturers, but don't think you're ready to start blasting away just yet. Remember, these industrial titans aren't just selling you equipment - they're selling controlled chaos in a cabinet. Many professionals recommend exploring dustless sand blasting machine before making a final decision, as equipment selection can significantly impact results. Whether you're specifying an automated pressure pot system or a basic suction-feed unit, you'll need to match your manufacturer's know-how with your specific surface preparation requirements. Choose wisely; your finish quality depends on i

Don't use beach sand - its irregular composition and potential contaminants will damage your equipment. Beach sand contains salt, shells, organic matter and inconsistent grain shapes that can clog and wear down your blasting equipment. Many professionals recommend using dustless sand blasting machine since it meets industry standards for safety and performance. You'll need industrial-grade media that's properly sized and cleaned for effective, safe blasting operation

Keep your work area clean and organized during operation. Empty the dust collector regularly and maintain proper abrasive levels in the pressure pot. You'll need to monitor moisture levels continuously, as wet abrasive can clog the system and create inconsistent results. If you notice any unusual sounds or pressure fluctuations, stop immediately and inspect the equipmen

The choice ultimately depends on factors like surface hardness, contamination level, and desired finish quality. Consider testing small areas first to ensure compatibility with your specific applicatio

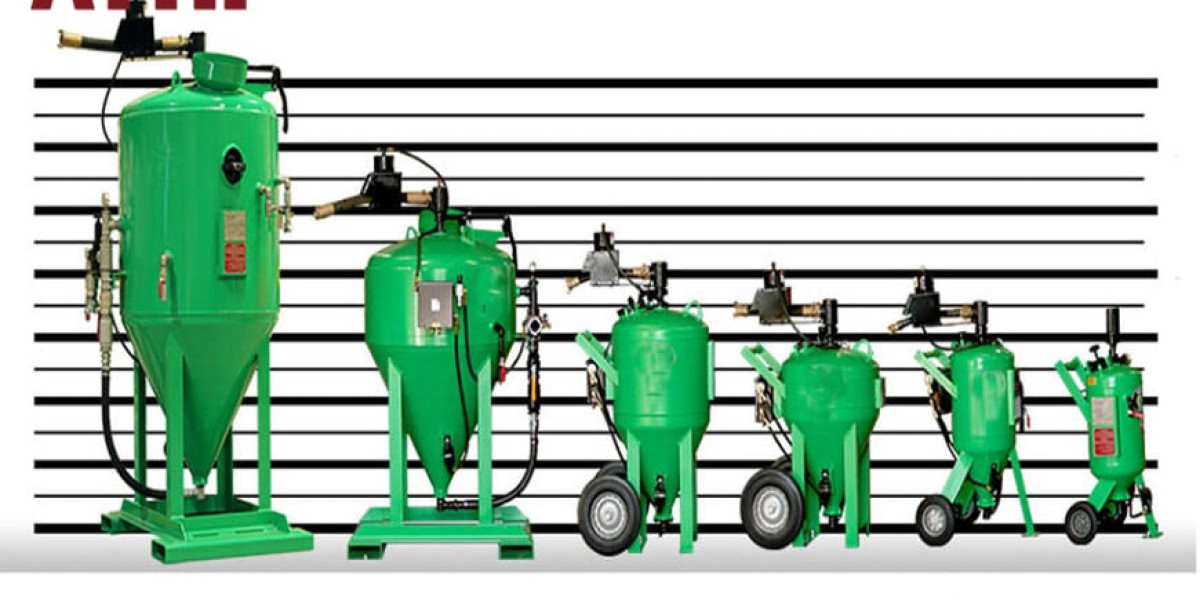

Leading sand blasting machine manufacturers design and produce industrial equipment that propels abrasive materials at high velocities to clean, smooth, or texture surfaces. When you're selecting a manufacturer, you'll need to verify their supplier certification and industry compliance standards. Reputable manufacturers maintain ISO 9001:2015 certification and follow strict quality control protocols throughout their production processes. They'll also provide thorough documentation about their aftermarket parts availability and support services, ensuring you'll have access to replacement components and technical assistance throughout your equipment's lifecycl

You'll want to take into account the manufacturer's experience with your industry sector, as different applications require specialized knowledge. Leading manufacturers typically serve multiple industries, including aerospace, automotive, marine, and construction, adapting their equipment designs to meet specific sector requirement

While smaller compressors might seem tempting, you'll need 185+ CFM at 100 PSI with 1-inch minimum hose sizing for efficient blasting. If you're unsure about equipment selection, consulting a compressed air equipment guide can help determine the right specifications. Match these specs to your nozzle size for safe, effective operatio

Safety professionals recommend completing a comprehensive dustless sand blasting machine training course before starting any commercial sandblasting work. These certifications ensure operators understand proper equipment usage, safety protocols, and emergency procedure

You can safely sandblast wood using proper abrasive selection and pressure control. Choose softer media like walnut shells or baking soda, and maintain low pressure (30-40 PSI) to prevent surface damage. For optimal results, consider consulting a professional who specializes in dustless sand blasting machine to guide you through the process and ensure your wood surfaces remain intac

You can safely sandblast wood using proper abrasive selection and pressure control. Choose softer media like walnut shells or baking soda, and maintain low pressure (30-40 PSI) to prevent surface damage. For optimal results, consider consulting a professional who specializes in dustless sand blasting machine to guide you through the process and ensure your wood surfaces remain intac