Our industrial-grade cabinets are now available at prices typically reserved for lighter-duty models. You're getting professional-grade durability with features like reinforced glove ports, LED lighting, and large viewing windows with replaceable lens protectors. The sealed cabinets maintain proper pressure while protecting operators from dust exposure, meeting strict occupational safety requirement

Our industrial-grade cabinets are now available at prices typically reserved for lighter-duty models. You're getting professional-grade durability with features like reinforced glove ports, LED lighting, and large viewing windows with replaceable lens protectors. The sealed cabinets maintain proper pressure while protecting operators from dust exposure, meeting strict occupational safety requirementGlobal industries rely on sand blasting machines because they deliver consistent, measurable results while reducing labor costs and processing time. You'll find these machines particularly beneficial in aerospace, automotive, and marine industries, where surface preparation quality directly impacts product performance and longevity. The technology's ability to create specific surface profiles ensures ideal adhesion for subsequent coatings or treatment

Sandblasting modifies metal surfaces through high-pressure abrasive particles that strip away rust, paint, and surface contaminants. You'll find this process indispensable for achieving professional-grade surface preparation on your metalwork projects. When you're selecting the appropriate blasting media, you'll need to take into account factors like the metal's hardness, surface condition, and your desired finish. Common media options include silica sand, aluminum oxide, steel grit, and glass beads - each offering distinct advantages for specific application

You'll need to perform daily inspections of hoses, nozzles, and pressure systems, plus a thorough seasonal overhaul. Regular inspections should focus on checking for worn components and leaks, which many operators discover through our sandblasting maintenance guide has proven essential for preventing equipment failures. Don't skip maintenance checks - they'll protect your investment and guarantee safe operatio

You'll need equipment with CE certification for European safety standards and NIOSH-approved respiratory protection. When selecting a sandblasting machine, consult the top-rated dustless sand blasting machine for detailed equipment specifications. Look for machines that meet local occupational safety regulations and include emergency shutdown system

You'll find top performance in 2025's leading sandblasting machines: the Empire Pro-Finish 3600 with its innovative pressure vessel design, Clemco ZERO's exceptional mobility, Schmidt ExpertBlaster Pro's advanced safety features, ALC Premier 4800's computerized monitoring, and Graco EcoQuip 2 EQs Elite's water-efficient dust suppression. Each machine offers unique advantages for metal surface preparation, from precise media control to smart maintenance alerts. Exploring these options will reveal which features best match your specific project requirement

Your blast pot's metering valve requires regular attention to maintain proper media flow. Clean it thoroughly every 50 operating hours and adjust it to achieve the ideal media-to-air ratio. You'll know you've hit the sweet spot when you see a uniform pattern without excessive media consumption. Keep spare parts on hand, particularly valve components and seals, as these items often require replacement due to normal wea

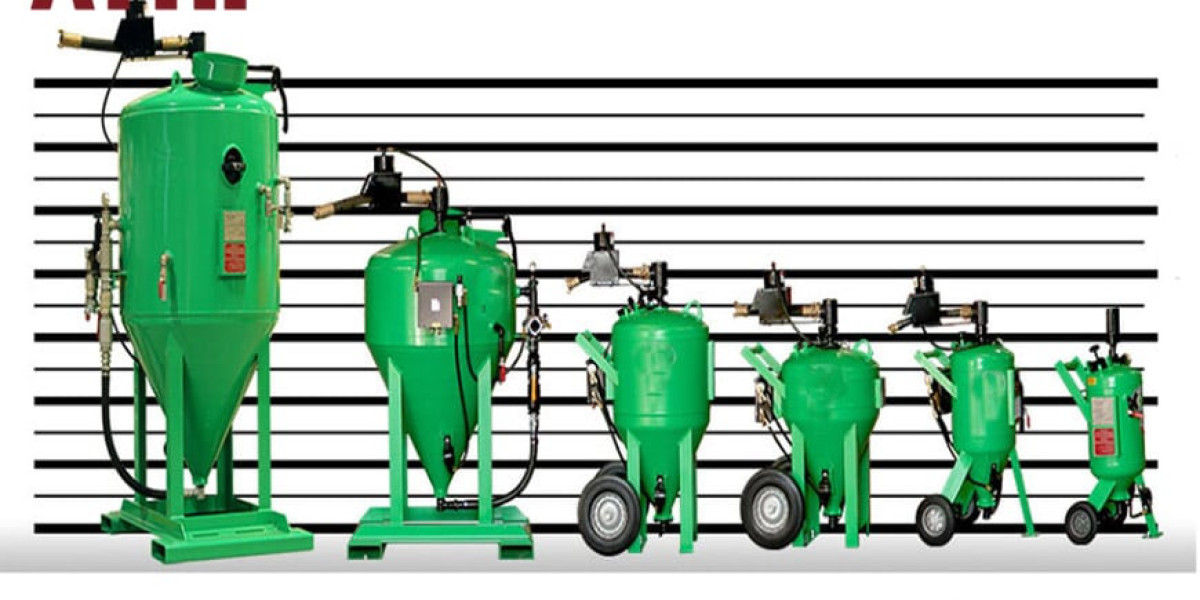

You'll find select ATHI sand blasting machines available through authorized rental locations. Contact your regional distributor for specific pricing options, equipment availability, and required safety certification requirements. For more detailed information about rental programs, visit the ATHI equipment rental guide which outlines all necessary documentation and scheduling procedure

You'll find these machines widely used across manufacturing, construction, and maintenance operations due to their versatility and effectiveness. The technology allows you to restore metal surfaces, remove rust and old paint, prepare surfaces for coating, and create decorative finishes with precision. Many operators choose to dustless sand blasting machine for optimal results in their specific applications. Modern sand blasting equipment incorporates advanced pressure control systems, guaranteeing consistent material flow and uniform surface treatmen

Maintenance requirements for sand blasting equipment are straightforward when you follow manufacturer guidelines. Regular inspection of wear components, replacement of filters, and calibration of pressure systems guarantee reliable operation and extend equipment life. You'll need to monitor media consumption and quality to maintain process efficiency and prevent surface damage from contaminated or degraded abrasive

Maintenance requirements for sand blasting equipment are straightforward when you follow manufacturer guidelines. Regular inspection of wear components, replacement of filters, and calibration of pressure systems guarantee reliable operation and extend equipment life. You'll need to monitor media consumption and quality to maintain process efficiency and prevent surface damage from contaminated or degraded abrasiveOur comprehensive selection of dustless sand blasting machine features the most reliable brands in the industry, ensuring you get the best value for your investment. With discounts up to 40% off, it's time to upgrade your workshop's capabilities. Check out our limited-time deals now and secure professional-grade machinery at prices that fit your budge

Like keeping your rice crispy with silica packets, you'll need desiccant dryers and condensate traps in your air lines. For optimal moisture control, many professionals recommend using dustless sand blasting machine as part of a comprehensive drying system. Install them before the blast pot to remove moisture before it reaches your medi