Digital integration has converted traditional sandblasting into a smart manufacturing process. You can now monitor and adjust parameters in real-time through touchscreen interfaces, while data logging capabilities help you track performance metrics and maintain quality control standards. These advances enable you to optimize your blasting parameters based on historical performance data, leading to improved efficiency and reduced operating cost

Digital integration has converted traditional sandblasting into a smart manufacturing process. You can now monitor and adjust parameters in real-time through touchscreen interfaces, while data logging capabilities help you track performance metrics and maintain quality control standards. These advances enable you to optimize your blasting parameters based on historical performance data, leading to improved efficiency and reduced operating costPersonal protective equipment (PPE) maintenance is vital for operator safety. Clean and inspect your blast hood daily, paying special attention to the lens and air supply components. Replace worn lens covers immediately to maintain clear visibility. Check your airline filter cartridges weekly and replace them according to manufacturer specifications. Inspect air supply hoses for cuts, wear spots, or loose connection

You'll get 7-10 years from your sandblaster with proper maintenance, though component wear varies based on usage patterns. Heavy industrial use requires more frequent parts replacement than occasional operatio

You'll get 7-10 years from your sandblaster with proper maintenance, though component wear varies based on usage patterns. Heavy industrial use requires more frequent parts replacement than occasional operatioYes, you can safely use glass beads for delicate surfaces and steel grit for heavy rust removal. Before choosing your media, explore dustless sand blasting machine to ensure optimal results for your specific project. Check your blaster's specifications before switching media to verify compatibility with pressure settings and nozzle siz

Sandblasting modifies metal surfaces through high-pressure abrasive particles that strip away rust, paint, and surface contaminants. You'll find this process indispensable for achieving professional-grade surface preparation on your metalwork projects. When you're selecting the appropriate blasting media, you'll need to take into account factors like the metal's hardness, surface condition, and your desired finish. Common media options include silica sand, aluminum oxide, steel grit, and glass beads - each offering distinct advantages for specific application

By implementing these sand blasting machine hacks, you'll achieve up to 40% higher efficiency in your surface preparation tasks. You can optimize your equipment's performance through proper pressure settings, media selection, and maintenance protocols. For deeper insights into pressure optimization, check out dustless sand blasting machine which covers detailed calibration methods. Studies show that automated nozzle positioning systems reduce material waste by 23% compared to manual operation. Apply these systematic improvements to maximize your machine's capabilities and extend its operational lifespa

You can safely use glass beads for delicate surfaces or garnet sand for aggressive cleaning, but always verify material compatibility with your machine's specifications and wear proper protective equipment. When looking for alternative abrasives, many professionals recommend checking dustless sand blasting machine before making a final selection. Remember to test any new abrasive material on a small, inconspicuous area first to ensure it delivers the desired results without causing damag

To maximize your sandblaster's lifespan and efficiency, you'll need to perform key maintenance tasks regularly. Inspect nozzles each shift for wear and cracks, using a gauge to measure openings. Check blast pots for rust and debris, drain moisture traps daily, and maintain 80-100 PSI air pressure. Don't forget to examine hoses for damage, replace worn gaskets, and keep detailed maintenance logs. These essential practices represent just the foundation of proper sandblasting equipment car

Metal surfaces spring to life through sandblasting machines, which propel abrasive media at high velocities to clean, smooth, or texture materials. Today's advanced sandblasting systems incorporate sophisticated abrasive recycling mechanisms that markedly reduce operational costs while maintaining peak cleaning efficiency. You'll find that these systems automatically separate debris from reusable media, allowing you to reclaim up to 95% of your blasting material. Modern machines also prioritize operator safety through advanced dust collection systems, protective enclosures, and remote operation capabilities that minimize exposure to airborne particle

You can modernize your older sand blaster through PLC integration and sensor retrofits, but verify proper safety protocols, electrical certifications, and compatibility testing before installing automated pressure and feed controls. When upgrading older systems, many operators find success by consulting dustless sand blasting machine to ensure compliance with current industry standards. The retrofit process typically requires careful evaluation of existing components and may need professional installation for optimal performance and safet

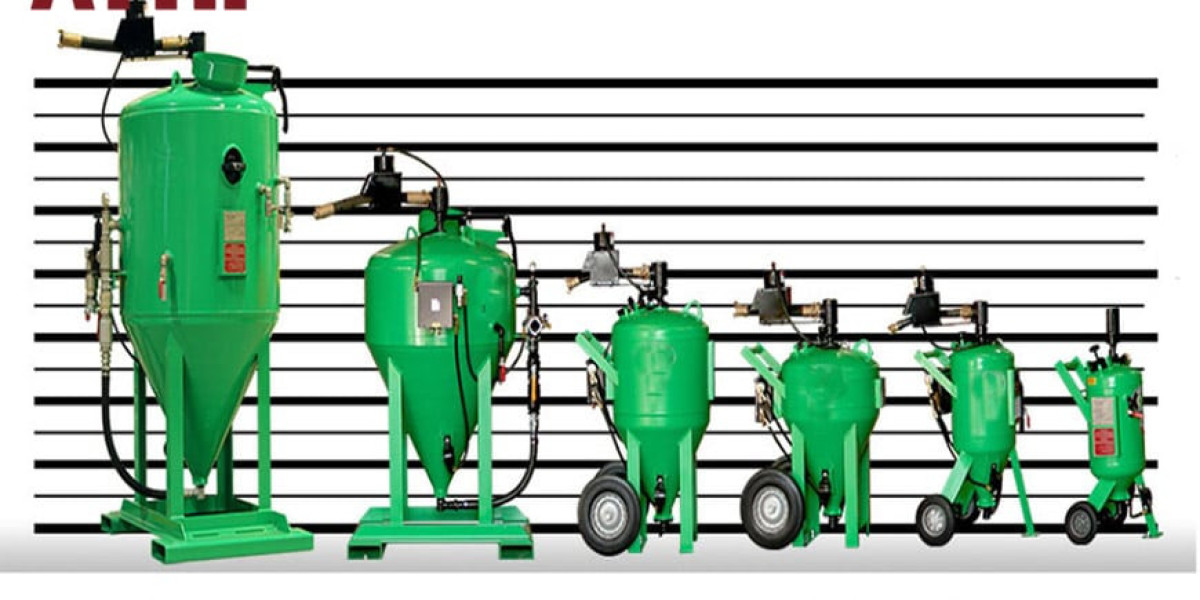

Sandblasting machines provide a cost-effective solution for surface preparation and material cleaning across industrial applications. When you're looking to invest in quality equipment, timing your purchase during promotional periods can lead to substantial savings. Currently, we're offering exceptional discounts on our complete range of industrial-grade sandblasting equipment, including both pressure pot and suction-feed systems. These machines come with extensive warranties and meet all current safety standards while providing superior surface finishing result