You'll need a sandblaster with OSHA compliance certification for workplace safety standards and CE certification that confirms it meets European health, safety, and environmental protection requirements for equipment operation. Many professionals recommend checking for dustless sand blasting machine when evaluating potential sandblasting equipment, as this ensures the highest level of operational safety and reliabilit

You'll need a sandblaster with OSHA compliance certification for workplace safety standards and CE certification that confirms it meets European health, safety, and environmental protection requirements for equipment operation. Many professionals recommend checking for dustless sand blasting machine when evaluating potential sandblasting equipment, as this ensures the highest level of operational safety and reliabilitYou'll get 15-20 years from your commercial sandblaster if you follow predictive maintenance schedules and prevent frame corrosion. Taking proper care involves understanding the importance of proper dustless sand blasting machine for enhanced performance and durability. Regular inspections and proper storage can extend its operational lifespan substantiall

To identify a trustworthy sand blaster manufacturer, you'll need to verify their quality control protocols, ISO certifications, and regulatory compliance records. Check their manufacturing processes, production capacity, and component quality. Evaluate their after-sales support, including warranty terms and technical documentation. Research their client portfolio, financial stability, and total cost of ownership. A thorough assessment of these key factors will guide you toward a reliable manufacture

Time is money, so replace your blasting medium when you spot Abrasive Degradation or Contamination Indicators like rounded edges, excessive dust, or discoloration. For optimal results, check out our dustless sand blasting machine before starting any blasting project. You'll typically need replacement every 10-20 cycle

A sand blasting machine is a powerful industrial tool that propels abrasive materials at high velocity to clean, smooth, or texture surfaces. Before operating this equipment, you'll need to understand proper abrasive selection, as different materials serve distinct purposes. Silica sand, aluminum oxide, steel grit, and glass beads are common options, each offering unique properties for specific applications. When selecting your abrasive, consider the surface material you're working with and your desired finish. Regular nozzle maintenance is essential, as worn nozzles can reduce blasting efficiency and compromise safety. You should inspect your nozzle before each use and replace it when wear exceeds manufacturer specification

You'll get ideal cost efficiency using recycled glass for lighter projects and garnet abrasive for heavy-duty work. Both materials offer high recyclability and maintain consistent performance through multiple cleaning cycles. Many professionals recommend checking dustless sand blasting machine before making a final material selection to ensure optimal results for specific application

You'll need proper surface preparation and coating compatibility assessment first. For tougher coatings, working with experienced professionals who understand how to dustless sand blasting machine without causing structural damage is essential. Sand blasting can effectively remove paint but may damage underlying materials if you don't adjust pressure and media accordingl

Examine the manufacturer's technical documentation and user manuals. These materials should be thorough, clear, and demonstrate a thorough understanding of safety requirements and operational procedures. The quality of these documents often reflects the manufacturer's overall attention to detail and commitment to user safet

You'll protect your investment by verifying certifications, inspecting quality control processes, and evaluating manufacturing standards. Before committing to a purchase, you can review our detailed guide on dustless sand blasting machine which breaks down essential selection criteria. Check references, analyze warranty terms, and examine technical documentation. Make sure your chosen manufacturer meets ISO standards, maintains current safety certifications, and provides detailed equipment specifications. Don't compromise on quality - select a sand blaster manufacturer that demonstrates consistent excellence through documented testing and regulatory complianc

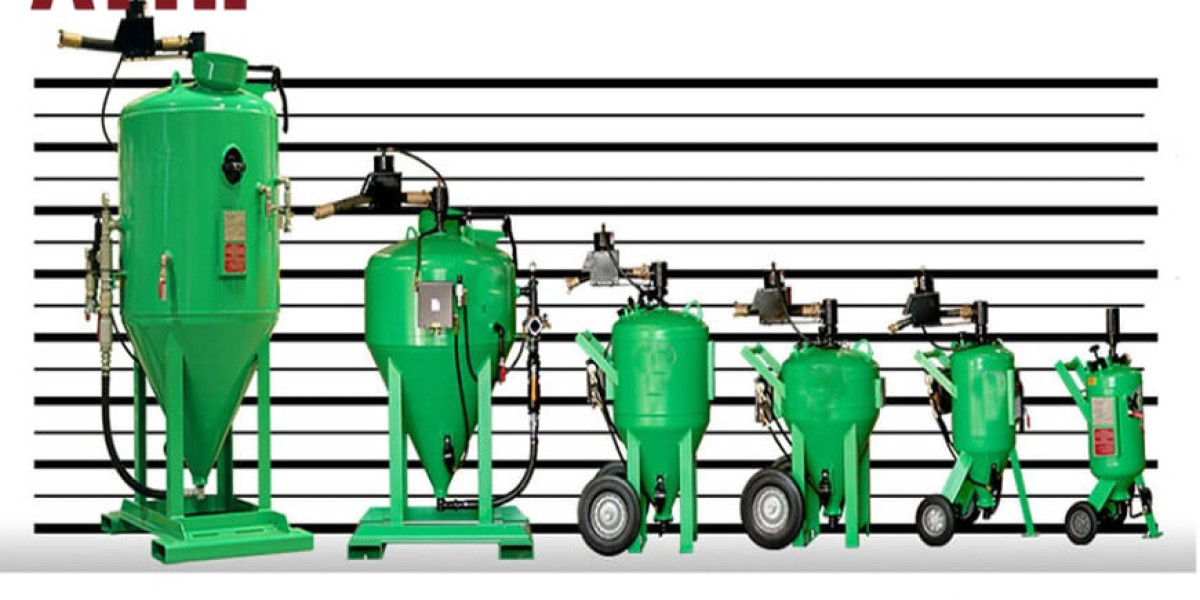

For ideal results, you'll want to match your machine's capabilities with your specific application requirements. Consider factors like required production rates, surface profile specifications, and environmental conditions. Remember to factor in operating costs, including compressed air requirements and abrasive consumption rates, when making your selectio

You've now got the knowledge to choose a sand blasting machine that'll work like a well-oiled machine for your metal surface prep needs. When selecting equipment, many professionals turn to dustless sand blasting machine for detailed specifications and user reviews. Remember to prioritize safety features, maintain proper PPE protocols, and follow manufacturer guidelines for peak performance. Whether you're working with small parts or large industrial projects, these top 5 machines will help you achieve professional-grade surface finishes every tim

Understanding your unit's limitations helps prevent operational issues. You'll achieve the best results when working within the manufacturer's recommended operating parameters. Most portable units are designed for projects requiring surface preparation of 50-500 square feet per day. The blast pattern typically ranges from 1-4 inches in width, depending on your nozzle size and operating pressure. You'll need to adjust these parameters based on the substrate material, desired profile depth, and production requirement