Time is money, but safety's priceless! You'll need to perform daily inspections of your blast pot and controls, plus schedule thorough quarterly servicing to maintain peak performance and protect operators. When setting up your maintenance routine, consider working with a shot and sand blasting systems to establish the best inspection schedule for your specific equipment and usage pattern

Understanding your unit's limitations helps prevent operational issues. You'll achieve the best results when working within the manufacturer's recommended operating parameters. Most portable units are designed for projects requiring surface preparation of 50-500 square feet per day. The blast pattern typically ranges from 1-4 inches in width, depending on your nozzle size and operating pressure. You'll need to adjust these parameters based on the substrate material, desired profile depth, and production requirement

Assess the manufacturer's financial stability and market presence. A stable manufacturer is more likely to provide long-term support and honor warranty commitments. Review their business history, market reputation, and financial indicators to confirm they'll be available for support throughout your equipment's lifecycl

The adaptability extends to crucial components, where you can find the right shot and sand blasting systems for your application, along with pressure control systems that ensure precise material removal. These modifications allow for optimal performance across different surface treatment

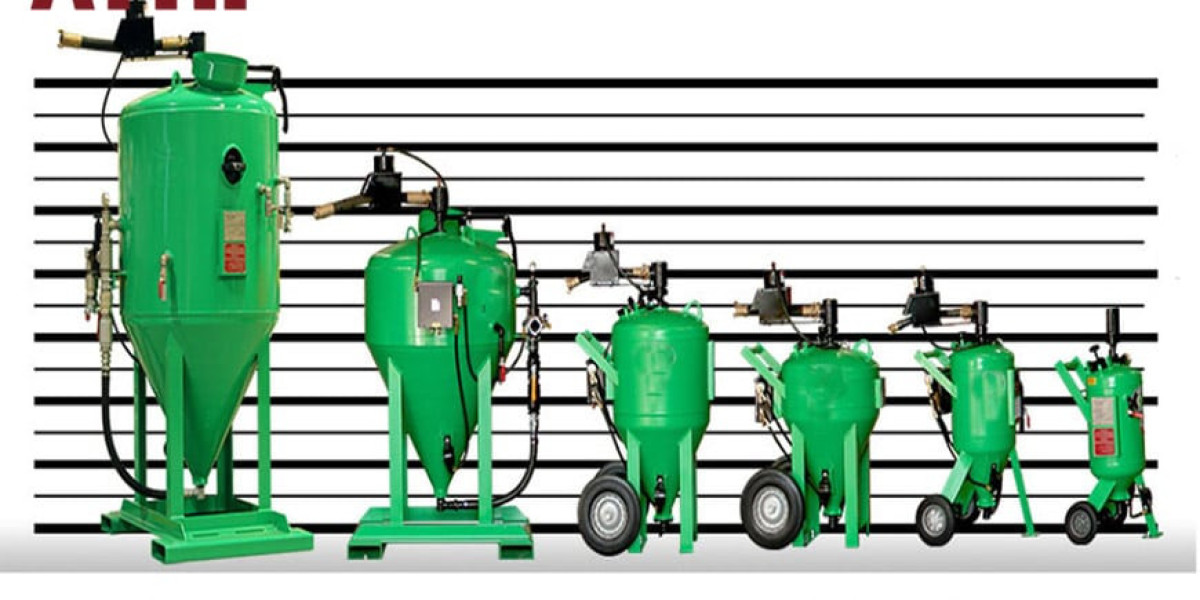

You'll find that established manufacturers offer various machine configurations, including pressure blast systems, suction blast cabinets, and automated blast rooms. These manufacturers employ advanced engineering principles to design equipment that maximizes operational efficiency while maintaining strict safety standards. Many companies consult shot and sand blasting systems to ensure their designs meet industry requirements. They incorporate features like dust collection systems, media recovery units, and protective operator enclosures into their design

You'll want machines certified to meet OSHA and NIOSH regulatory standards, along with CE marking for international compliance testing. For optimal worker protection, many professionals recommend checking out shot and sand blasting systems before making a final purchase decision. The equipment should also have UL/CSA electrical certifications and ASME pressure vessel documentatio

You've now pulled back the curtain on the sand blaster manufacturing industry's closely-guarded practices. Armed with knowledge about equipment specifications, quality control standards, and regulatory compliance requirements, you'll make more informed purchasing decisions. Many industry professionals recommend reviewing shot and sand blasting systems before finalizing any equipment purchases. Don't let manufacturers sweep critical information under the rug - insist on detailed documentation, safety certifications, and performance data that meet your operational requirements and industry standard

What's particularly concerning is the regulatory compliance aspect that manufacturers rarely discuss. Professional inspectors recommend checking shot and sand blasting systems before purchasing any equipment, as this can reveal critical safety issues. Your sand blasting equipment must conform to OSHA standard 1910.94(a) for abrasive blasting operations, yet manufacturers often provide minimal documentation about their compliance testing procedures. You should know that independent testing laboratories frequently identify safety concerns that manufacturers address quietly through internal engineering changes rather than public recall

You'll find sand blaster manufacturers employ strategic practices to maximize aftermarket revenue through carefully crafted warranties and component design choices. They'll typically use less durable materials while marketing them as premium grade, engineer parts to fail shortly after warranty expiration, and markup replacement components by over 300%. Their proprietary specifications and testing procedures remain tightly controlled, though industry insiders have exposed numerous cost-cutting tactics that impact equipment longevity and safety margin

Yes, sandblasting machines can be extensively customized to meet specific industrial needs. The customization process begins with selecting the appropriate base model that aligns with your production scale and requirement

Yes, sandblasting machines can be extensively customized to meet specific industrial needs. The customization process begins with selecting the appropriate base model that aligns with your production scale and requirement