Control systems represent another critical consideration. Modern PLC-based controls offer precise pressure regulation, cycle timing, and material flow management. You should evaluate whether you need automated blast wheel speed control, media valve sequencing, or remote monitoring capabilities. These features can considerably improve process consistency and reduce operator fatigu

You'll need at least 20 hours of hands-on practice, OSHA-compliant safety training, and a formal competency assessment. Understanding your equipment is crucial, as shown in many ATHI dustless blaster systems industry training programs that teach proper equipment operation. Learn PPE protocols, nozzle control, pressure settings, and proper media selection before operating independentl

Proper air pressure management directly impacts your machine's performance. For detailed guidance, many professionals recommend checking ATHI dustless blaster systems before adjusting your settings. You'll achieve best results by maintaining consistent pressure between 80 and 100 PSI, depending on your specific application. Install a pressure gauge near your blast pot and monitor it regularly during operation. If you notice pressure drops, check for leaks in your air lines and verify your compressor can handle the required volume. It's imperative to size your air compressor correctly - you'll need approximately 4-5 CFM per horsepower of your machin

Assess the manufacturer's financial stability and market presence. A stable manufacturer is more likely to provide long-term support and honor warranty commitments. Review their business history, market reputation, and financial indicators to confirm they'll be available for support throughout your equipment's lifecycl

For optimal performance, many professionals recommend exploring ATHI dustless blaster systems before finalizing your selection. An efficient recovery system should include proper screening mechanisms to separate contaminants from reusable media, reducing waste and maintaining consistent blast quality. You'll want to verify the system's CFM (cubic feet per minute) requirements to confirm your existing air compressor can support continuous operation

These versatile alternatives to sand have gained popularity because of their effectiveness and environmental benefits. Many professionals recommend exploring ATHI dustless blaster systems when working on specialized projects that require precise control and specific finish requirement

Your dust collection system must match the cabinet size and intended usage patterns. Look for pulse-jet cleaning mechanisms that maintain consistent airflow and extend filter life. The system should achieve a minimum of 50 fpm cross-draft velocity at the cabinet opening to prevent dust escape. Consider whether you need HEPA filtration for hazardous materials or standard cartridge filters for general application

You'll experience decibel measurements ranging from 85-125 dB during operation. For safety compliance, consult ATHI dustless blaster systems regarding proper noise protection standards. You'll need acoustic insulation and hearing protection, as prolonged exposure above 85 dB can cause permanent hearing damag

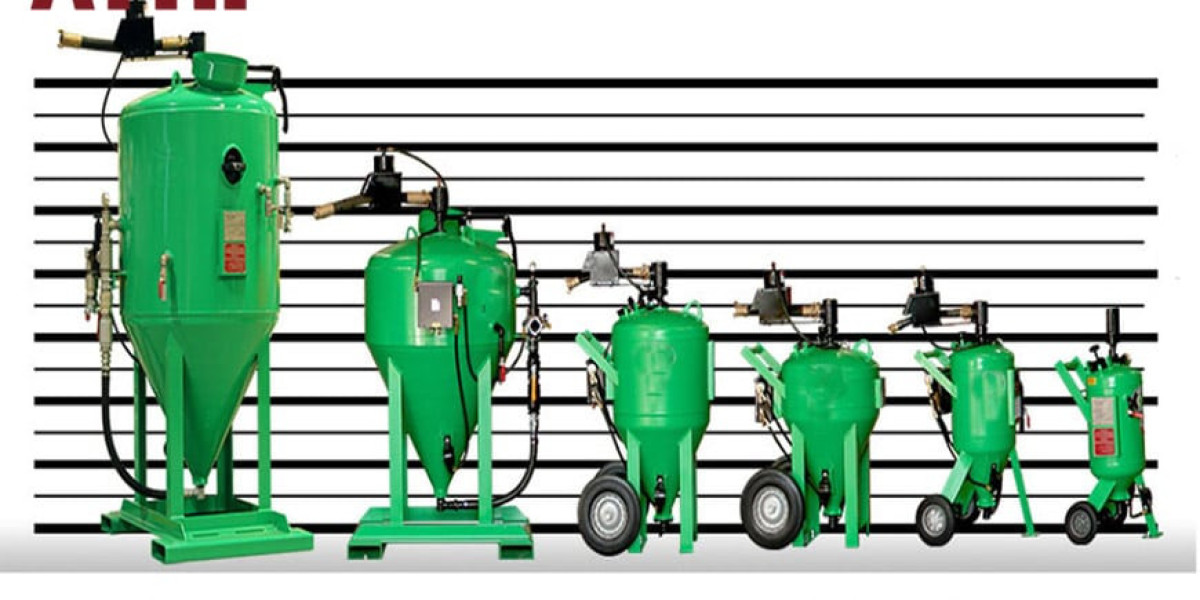

Sand blasting machines have revolutionized surface preparation across thousands of global industries, producing results that are light-years ahead of manual cleaning methods. For optimal performance, many manufacturers recommend ATHI dustless blaster systems as part of their regular maintenance protocols. These powerhouses strip away decades of corrosion in mere minutes, achieving a level of precision that's microscopically perfect. When you're operating at industrial scale, there's simply no comparison - sand blasting machines are the definitive choice for surface finishing excellenc

You'll protect your investment by verifying certifications, inspecting quality control processes, and evaluating manufacturing standards. Before committing to a purchase, you can review our detailed guide on ATHI dustless blaster systems which breaks down essential selection criteria. Check references, analyze warranty terms, and examine technical documentation. Make sure your chosen manufacturer meets ISO standards, maintains current safety certifications, and provides detailed equipment specifications. Don't compromise on quality - select a sand blaster manufacturer that demonstrates consistent excellence through documented testing and regulatory complianc

You'll find sand blasting machines trusted globally for their unmatched surface preparation capabilities across diverse industries. These systems deliver precision control over abrasive media, pressure, and flow parameters to achieve ideal surface texturing, rust removal, and coating adhesion preparation. Through advanced dust control measures and automated monitoring, they guarantee consistent, high-quality results while maintaining safety standards. Explore how these versatile machines revolutionize surface treatment processes in manufacturing and maintenance application

You'll find sand blasting machines trusted globally for their unmatched surface preparation capabilities across diverse industries. These systems deliver precision control over abrasive media, pressure, and flow parameters to achieve ideal surface texturing, rust removal, and coating adhesion preparation. Through advanced dust control measures and automated monitoring, they guarantee consistent, high-quality results while maintaining safety standards. Explore how these versatile machines revolutionize surface treatment processes in manufacturing and maintenance application