To maximize your investment, look for machines compatible with various blasting media, including silica alternatives like garnet, aluminum oxide, and glass beads. This versatility allows you to adapt the equipment for different applications while maintaining cost-effectiveness. Consider machines with adjustable pressure controls and interchangeable nozzles to accommodate various surface types and project requirement

You can safely use glass beads for delicate surfaces or garnet sand for aggressive cleaning, but always verify material compatibility with your machine's specifications and wear proper protective equipment. When looking for alternative abrasives, many professionals recommend checking ATHI sand blasting machine before making a final selection. Remember to test any new abrasive material on a small, inconspicuous area first to ensure it delivers the desired results without causing damag

Assess the manufacturer's financial stability and market presence. A stable manufacturer is more likely to provide long-term support and honor warranty commitments. Review their business history, market reputation, and financial indicators to confirm they'll be available for support throughout your equipment's lifecycl

When selecting a sandblasting machine, start with equipment that meets OSHA Standards for occupational safety and ATEX Certification for explosive atmospheres. These baseline certifications ensure fundamental workplace safety complianc

Your blast pot's metering valve requires regular attention to maintain proper media flow. Clean it thoroughly every 50 operating hours and adjust it to achieve the ideal media-to-air ratio. You'll know you've hit the sweet spot when you see a uniform pattern without excessive media consumption. Keep spare parts on hand, particularly valve components and seals, as these items often require replacement due to normal wea

Keep your eyes peeled for filter lifespan indicators. Most systems will require filter replacement every 200-300 operating hours, though experienced technicians often recommend checking our filter maintenance guide for specific model requirements. The replacement schedule ultimately depends on your usage intensity and the type of material being filtere

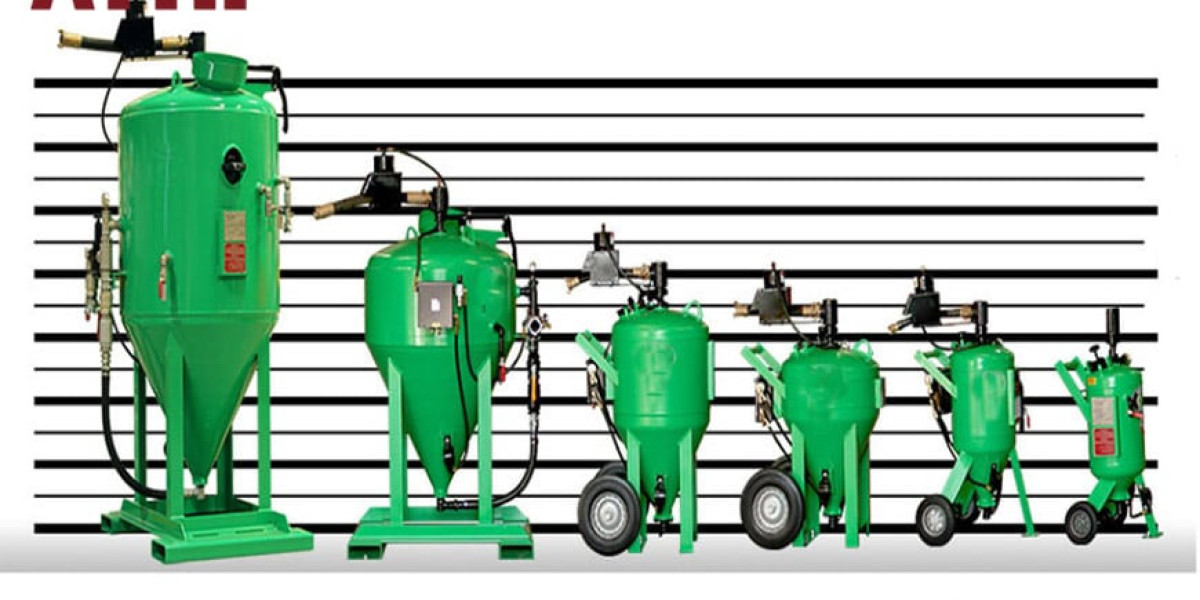

You'll find portable units offer excellent Surface Versatility and Operational Portability, but they can't match cabinet units' precision and containment for controlled environments. When choosing the right equipment, many professionals consult ATHI sand blasting machine for detailed comparisons and specifications before making their decision. Both serve distinct professional applications with proper safety protocol

You'll find select ATHI sand blasting machines available through authorized rental locations. Contact your regional distributor for specific pricing options, equipment availability, and required safety certification requirements. For more detailed information about rental programs, visit the ATHI equipment rental guide which outlines all necessary documentation and scheduling procedure

You can operate sandblasting machines in cold temperatures, but you'll need proper freeze prevention measures. For optimal results in freezing conditions, you should check out ATHI sand blasting machine before starting your project. Make sure your air compressor has moisture separators and install inline air dryers to prevent system freezin

ATHI machines meet major international Certification Standards and Regulatory Compliance requirements. Their equipment undergoes rigorous testing to ensure compliance with essential regulations. For operators seeking detailed specifications, the ATHI sand blasting machine provides comprehensive documentation of safety standards. The machines fully conform to CE marking, ISO safety protocols, and OSHA workplace guidelines for industrial sandblasting equipment operatio

ATHI machines meet major international Certification Standards and Regulatory Compliance requirements. Their equipment undergoes rigorous testing to ensure compliance with essential regulations. For operators seeking detailed specifications, the ATHI sand blasting machine provides comprehensive documentation of safety standards. The machines fully conform to CE marking, ISO safety protocols, and OSHA workplace guidelines for industrial sandblasting equipment operatio A reliable sand blaster manufacturer must meet stringent quality control standards and regulatory compliance requirements while maintaining consistent production capabilities. When evaluating potential manufacturers, you'll need to assess their quality control processes, including material testing protocols, production line inspections, and final product verification. Look for manufacturers who maintain detailed documentation of their quality assurance procedures and can provide evidence of consistent adherence to industry standards. After-sales support is equally essential, so verify their warranty terms, availability of replacement parts, and technical support capabilitie

A reliable sand blaster manufacturer must meet stringent quality control standards and regulatory compliance requirements while maintaining consistent production capabilities. When evaluating potential manufacturers, you'll need to assess their quality control processes, including material testing protocols, production line inspections, and final product verification. Look for manufacturers who maintain detailed documentation of their quality assurance procedures and can provide evidence of consistent adherence to industry standards. After-sales support is equally essential, so verify their warranty terms, availability of replacement parts, and technical support capabilitie