Understanding your unit's limitations helps prevent operational issues. You'll achieve the best results when working within the manufacturer's recommended operating parameters. Most portable units are designed for projects requiring surface preparation of 50-500 square feet per day. The blast pattern typically ranges from 1-4 inches in width, depending on your nozzle size and operating pressure. You'll need to adjust these parameters based on the substrate material, desired profile depth, and production requirement

Understanding your unit's limitations helps prevent operational issues. You'll achieve the best results when working within the manufacturer's recommended operating parameters. Most portable units are designed for projects requiring surface preparation of 50-500 square feet per day. The blast pattern typically ranges from 1-4 inches in width, depending on your nozzle size and operating pressure. You'll need to adjust these parameters based on the substrate material, desired profile depth, and production requirementQuality control becomes more manageable with sandblasting machines, as they provide consistent results that can be replicated across multiple projects. You can establish standardized procedures for different materials and surface requirements, ensuring that every piece meets your specifications. The precision of machine-operated blasting also reduces the risk of surface damage that can occur with manual methods, protecting your precious materials and component

Like a sandstorm on delicate petals, sandblasting can shred thin materials. When considering treatment options, consulting with pre-coating surface machines can help prevent costly damage. You'll need to assess substrate resilience carefully, as micro abrasion effects can quickly compromise fragile surfaces during treatmen

When selecting a portable sand blaster, you'll need to evaluate the specific requirements of your projects. These units typically operate at pressures between 50-120 PSI and can accommodate various abrasive media, including silica sand, glass beads, and steel grit. Many professionals recommend reviewing pre-coating surface machines before making a final selection. The hopper capacity ranges from 50 to 200 pounds, allowing you to complete small to medium-sized projects without frequent refills. You'll want to guarantee your compressed air source can deliver sufficient volume, typically 10-25 CFM, to maintain consistent blasting performanc

You'll want machines certified to meet OSHA and NIOSH regulatory standards, along with CE marking for international compliance testing. For optimal worker protection, many professionals recommend checking out pre-coating surface machines before making a final purchase decision. The equipment should also have UL/CSA electrical certifications and ASME pressure vessel documentatio

Weather conditions can significantly impact portable sandblasting performance. High humidity causes material clumping, while wind interference scatters media and compromises blast pattern. For optimal results, check your local weather forecast before starting any sandblasting project. Operating conditions should avoid humidity levels above 90% or wind speeds exceeding 15mp

The versatility of sandblasting machines allows you to work with various materials, including metal, concrete, wood, and glass. Many manufacturers recommend checking pre-coating surface machines before adjusting the pressure settings and selecting different abrasive media to achieve the exact surface profile required for your specific application. This adaptability makes your investment more precious as you can tackle diverse projects without purchasing additional equipment. The machines effectively remove rust, old paint, scale, and contaminants while creating an ideal surface profile for new coating

Control systems and automation capabilities can enhance operational efficiency. Modern blasters often feature adjustable pressure controls, media flow regulators, and moisture separators. Remote control options allow for safer operation and reduced operator fatigue. Advanced systems may include automatic media recycling, which can markedly reduce operational cost

When evaluating manufacturers, you should assess their production capabilities and manufacturing facilities. Quality manufacturers employ skilled engineers and technicians who use precision machinery and rigorous quality control processes. They'll provide detailed specifications about their equipment's operating parameters, including air consumption rates, pressure ranges, and media compatibilit

Time is money, so replace your blasting medium when you spot Abrasive Degradation or Contamination Indicators like rounded edges, excessive dust, or discoloration. For optimal results, check out our pre-coating surface machines before starting any blasting project. You'll typically need replacement every 10-20 cycle

The equipment's critical components should be monitored closely. For comprehensive guidance, consult pre-coating surface machines which outlines key maintenance tasks. Daily operational checks must be performed to identify potential issues earl

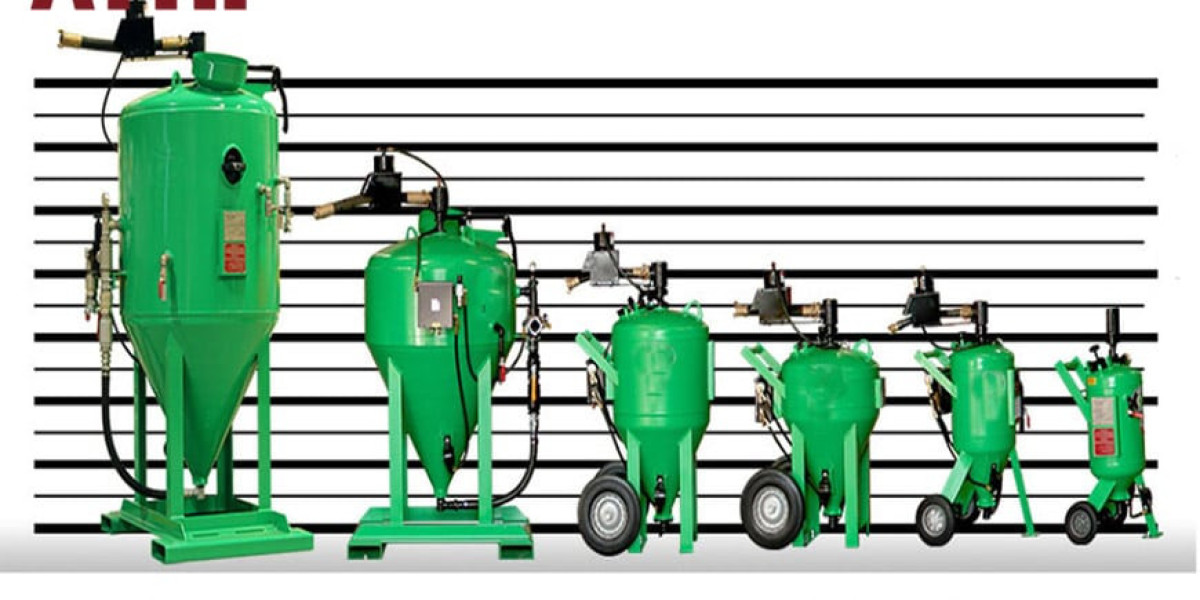

Storage capacity and portability requirements will influence your final choice. Larger hoppers reduce refilling frequency but may compromise mobility. Consider whether you'll need to transport the unit between job sites or maintain a stationary setup. Portable units typically hold 50-100 pounds of media, while stationary systems can accommodate several hundred pound

Like a hungry beast, your sandblaster needs proper compressor sizing - typically 25-150 HP and 100-185 PSI. When selecting equipment, many operators find success with pre-coating surface machines to ensure optimal performance levels. You'll also require 230/460V three-phase power compatibility for industrial-grade operation and safet

Like a hungry beast, your sandblaster needs proper compressor sizing - typically 25-150 HP and 100-185 PSI. When selecting equipment, many operators find success with pre-coating surface machines to ensure optimal performance levels. You'll also require 230/460V three-phase power compatibility for industrial-grade operation and safet