You'll increase efficiency markedly when switching from sand blasting to modern surface preparation techniques. These newer methods reduce airborne particulates, minimize cleanup time, and lower media consumption while providing superior finishing results. You'll cut labor hours through faster setup and experience decreased waste management costs. Modern equipment's simplified designs also mean less maintenance and downtime. Understanding these key advantages will help maximize your operational improvement

Regular system maintenance maintains consistent dust-free performance. You'll need to inspect water delivery systems, nozzles, and containment equipment before each use. Replace worn components promptly to prevent system failures that could compromise dust control. Document all maintenance activities and keep detailed records of equipment inspections and repairs for regulatory compliance and quality control purpose

You'll find that the economic impact extends beyond direct operational changes. The ban has created new market opportunities for manufacturers of alternative blasting media and equipment, while simultaneously affecting traditional sand suppliers and older equipment manufacturers. When you're planning your industrial cleaning processes, you'll need to factor in these market shifts and their associated cost

Your choice of abrasive media significantly impacts dust control effectiveness. Modern dust-free systems work best with specifically engineered media that's compatible with water-based delivery systems. Consider using recyclable media to reduce waste and operating costs while maintaining environmental responsibilit

You're now facing stricter enforcement of worker protection standards, with regulatory bodies implementing thorough silica exposure limits and mandatory control measures. These regulations require extensive personal protective equipment, dust containment systems, and regular air quality monitoring, substantially increasing operational costs. The financial impact of compliance, combined with potential workers' compensation claims and legal liabilities, has made traditional sand blasting increasingly unsustainable for many operation

You'll need a NIOSH-approved respirator, sealed eye protection, coveralls, hearing protection, gloves, and steel-toed boots when near sandblasting. Keep your respiratory protection and eye protection properly fitted at all time

Your protective equipment requirements extend beyond respiratory protection. You'll need to wear appropriate personal protective equipment (PPE), including blast suits, safety glasses, face shields, heavy-duty gloves, and steel-toed boots. The blast suits must be properly maintained and regularly inspected for wear and tear that could compromise their protective capabilitie

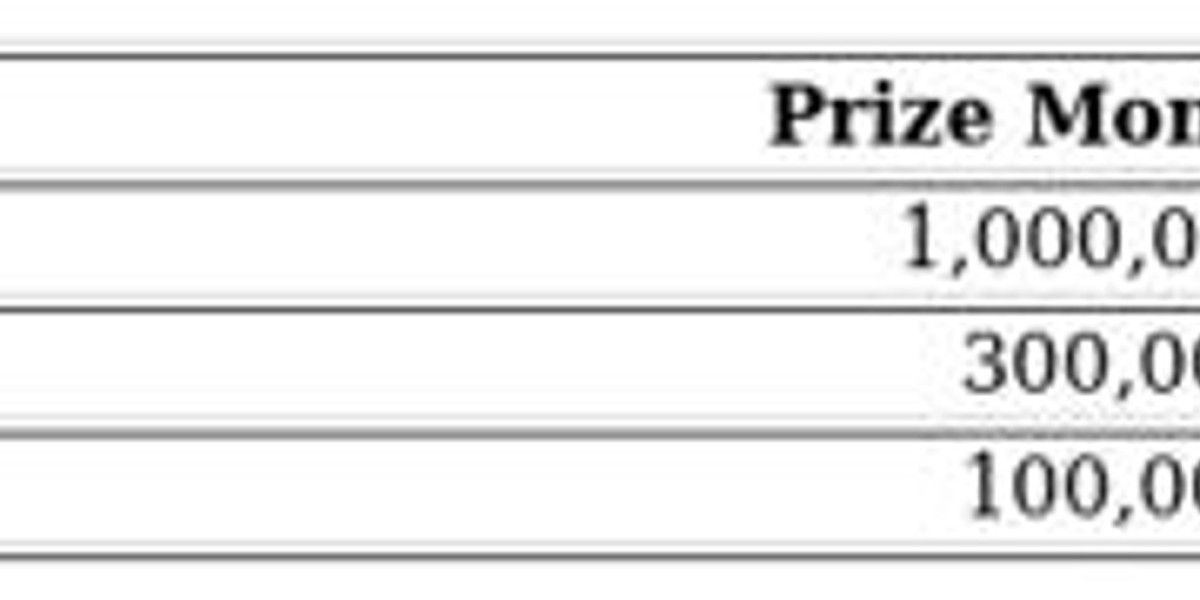

You'll face substantial criminal fines and potential civil liability if caught sand blasting. Penalties include imprisonment up to 2 years, unlimited financial penalties, and legal action from affected workers or communitie

You'll find limited exemptions through military exemptions and laboratory waivers, but you must obtain strict regulatory approval and follow enhanced safety protocols to conduct any permitted sandblasting operation

You need to select appropriate personal protective equipment (PPE) before initiating any blasting operation. This includes respiratory protection, even with dust-free methods, along with protective suits, gloves, and face shields rated for your specific application. Regular equipment maintenance guarantees peak performance and prevents unexpected releases of containment material

Modern alternatives like soda blasting, dry ice blasting, and vapor blasting are proving more cost-effective and environmentally responsible. Industry experts recommend reviewing workplace dust regulations uk when considering these safer options. These methods not only eliminate silica dust hazards but also offer superior cleaning performance in many applications. You'll notice that dry ice blasting, for instance, leaves no secondary waste and can clean sensitive equipment without causing damage, while soda blasting provides excellent results on softer surfaces without the aggressive nature of san

You'll find sand blasting operations are prohibited in the UK due to Health and Safety Executive regulations addressing severe silicosis risks. The ban stems from dangerous crystalline silica particles released during blasting, which cause irreversible lung damage when inhaled. This restriction has prompted industries to adopt safer alternatives like hydro-blasting and synthetic media, influencing global surface preparation practices and workplace safety standards. Understanding these changes reveals critical implications for international industrial operation

You'll find sand blasting operations are prohibited in the UK due to Health and Safety Executive regulations addressing severe silicosis risks. The ban stems from dangerous crystalline silica particles released during blasting, which cause irreversible lung damage when inhaled. This restriction has prompted industries to adopt safer alternatives like hydro-blasting and synthetic media, influencing global surface preparation practices and workplace safety standards. Understanding these changes reveals critical implications for international industrial operation